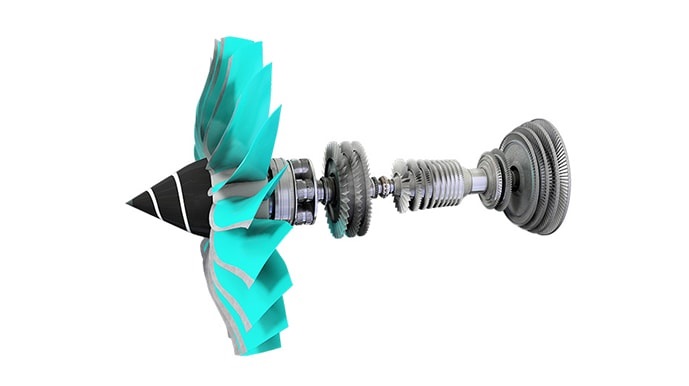

Say the title Rolls-Royce and most of the people consider cars, however the British multinational aerospace and protection firm has been out of the automotive enterprise since Rolls-Royce Motors was offered off within the Seventies. At present, Rolls-Royce Holdings is the second-largest maker of plane engines on this planet, with a foot in marine propulsion and vitality as effectively. Its engines are utilized in fighter jets, enterprise jets, and greater than 50% of long-haul planes.

Now the corporate is deploying digital twin expertise, analytics, and machine studying to dramatically cut back the quantity of carbon its plane engines produce whereas additionally optimizing upkeep to assist its clients maintain their planes within the air longer.

“Rolls-Royce has been monitoring engines and charging per hour for not less than 20 years,” says Stuart Hughes, chief data and digital officer at Rolls-Royce. “That a part of the enterprise isn’t new. However as we’ve developed, we’ve begun to deal with the engine as a singular engine. It’s rather more in regards to the personalization of that engine.”

Utilizing its Clever Engine platform, the corporate displays how every engine flies, the situations by which it’s flying, and the way the pilot makes use of it.

“We’re tailoring our upkeep regimes to guarantee that we’re optimizing for the life an engine has, not the life the guide says it ought to have,” Hughes says. “It’s actually variable service taking a look at every engine as a person engine.”

Rolls-Royce’s platform has helped it prolong the time between upkeep for some engines by as much as 50%, thereby enabling it to dramatically cut back its stock of components and spares. Maybe most significantly, nonetheless, it has tremendously improved the effectivity of its engines, saving 22 thousand tons of carbon to this point, in keeping with the corporate. Rolls-Royce is even utilizing AI to raised perceive methods to deal with steel scrap and waste from components once they attain the top of their lifespan.

“Since 2014, we’ve helped one among our airways keep away from 85 million kilograms of gas and over 200 million kilograms of carbon dioxide,” Hughes says. “We did that by taking knowledge on how the pilot is flying the aircraft, how the aircraft is operated, how they do the operational funding round that. We discovered knowledge and insights that helped them to make higher choices. In areas the place they felt there have been obstacles to alter, we helped them design new insurance policies, new procedures.”

To gas its Clever Engine platform, Rolls-Royce is utilizing a mixture of two-way, real-time knowledge captured from its engines as they fly, and bigger datasets captured in batch after planes land, to energy its analytics. It feeds the info right into a Microsoft Azure knowledge lake after which right into a Databricks “lakehouse,” the place it may be used with Databricks machine studying and AI instruments. (Databricks makes use of the time period to consult with its open structure that mixes the options of an information lake and knowledge warehouse.)

Between the real-time knowledge and the info collected after touchdown, every flight generates about half a gigabyte of knowledge. The true-time knowledge is used for the corporate’s “Engine Situation Monitoring” service, which analyzes the info for irregularities in engine efficiency for the aim of predictive upkeep. The analytics can decide in-flight whether or not a full inspection will likely be essential upon touchdown, serving to the airline plan forward and reduce journey disruptions. The opposite knowledge can be utilized for extra detailed predictive modeling.

“We’re utilizing that knowledge to test that the engine continues to be inside all our high quality and security tolerances, but in addition to grasp how the pilot has flown that engine,” Hughes says. “Meaning we will provide to increase the upkeep window on that engine longer for a selected buyer. The profit to the shopper is the shopper sees much less interruption as a result of the engine is on the aircraft for longer, to allow them to use it extra. The profit for us is that we will optimize how we really do the upkeep.”

With Rolls-Royce’s strategy, its clients can inform the corporate the mission of every engine — the surroundings by which it’s anticipated to fly, for example. Rolls-Royce can then tailor the upkeep schedule and analytics to these situations. An engine on a aircraft that operates in Qatar, for example, will be anticipated to take care of a certain quantity of sand within the environment.

“We use machine studying to take a look at all the knowledge that we’ve obtained from the previous and use all the knowledge we’ve collected to assist us perceive the upkeep regime that engine will want going ahead,” Hughes says. “Then we will adapt our pricing to be rather more particular to that.”